|

|

|

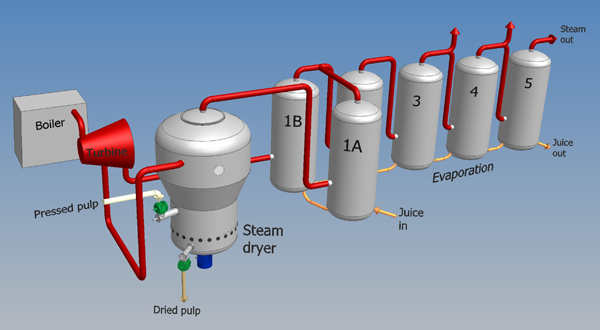

During many years the sugar industry has develop ed extremely energy efficient production processes. Some 200 years ago the sugar production was a very energy consuming process as juice concentra tion took place in direct fired pans. The energy from burning of wood (or bagasse) was used only once. Today you would never think of concentrating the juice in anything but a multiple stage evaporator. Furthermore - to improve energy utilization even more the high pressure steam would have produ ced electrical power before being used in the juice concentrating evaporator, and the evaporator sup plies steam to pan boiling and juice heating |

|

|

|

|

|

|

But what are you doing today when you dry your beet pulp in a conventional drum dryer?

-

The fuel is spend on evaporating water in one step without generating electrical power and the heat in vapor is wasted.

Consequently it takes several times more energy than to remove an equivalent amount of water from the juice.

-Does it have to be like that?

-

Not when utilizing the patented EnerDry Steam Drying Technology.

|

|

|

|

How does the steam dryer work?

|

|

|

|

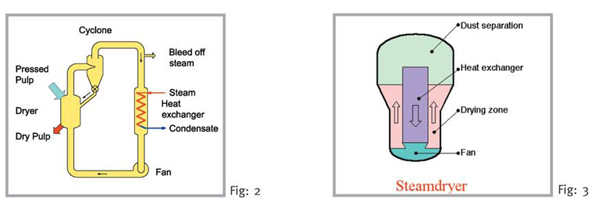

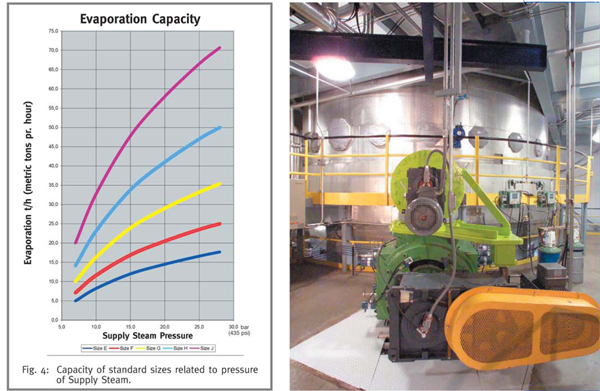

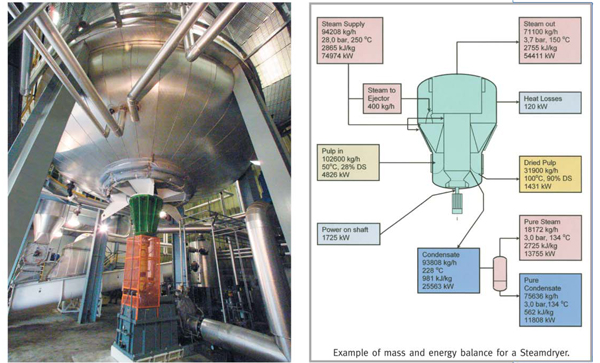

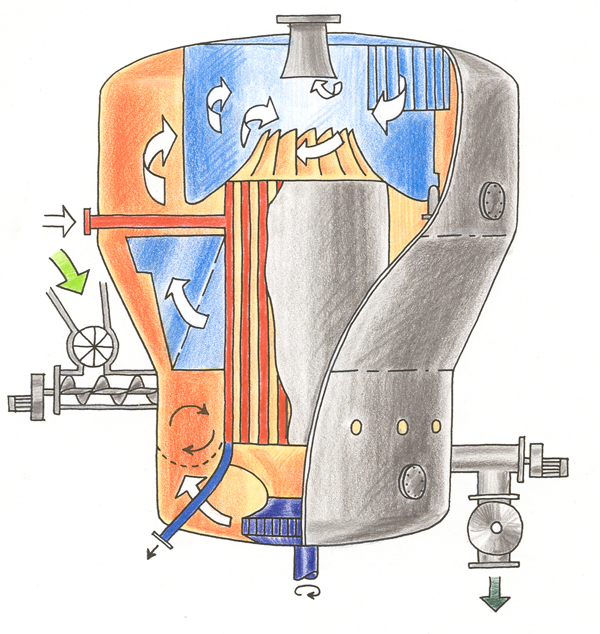

Steamdrying is basically very simple. You continu ously feed the pulp into a pressure vessel and add the necessary heat. Then you discharge the dried pulp, and bleed off the water that was in the pulp as useful steam at e.i. 3,5 bar.

You will then avoid any air pollution, and the drying

does not consume any energy. It only borrows the energy which, after the drying, is available as ste am to be supplied to the juice evaporators. However it is necessary to bring the large amount of energy into the beet particles. That makes it necessary to include a fluid bed in the pressure vessel in order to have an intense contact between pulp and steam. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EnerDry suplly assistance in all engineering aspects around the Steam Dryer |

|

|

-

Feasibility Studies

-

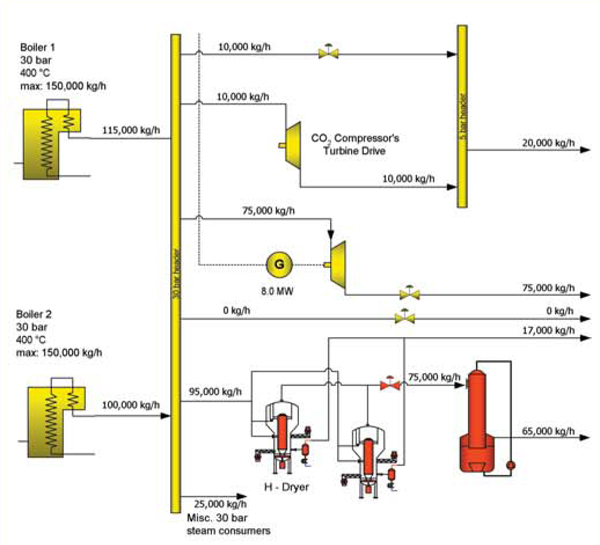

Integration in factory steam systems

-

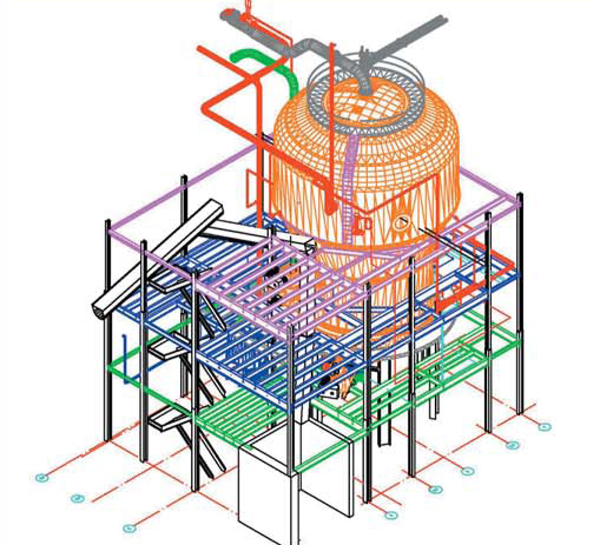

Building lay-out

-

Steam/condensate system layout

-

Engineering of conveyor systems etc.

|

|

|

|

|

|

|

|

|

|

EnerDry ApS is founded by Arne Sloth Jensen, who is the inventor of the pressurised fluid bed drying of beet pulp back in 1981, since then he has been in charge of its development. The technology and Arne Sloth Jensen has been awarded various prizes. The first one in 1987, when His Royal Highness Prince Henrik of Denmark presented the Environmental Prize of the Comrnision of the European Communities. In 1990, the VDZ Germany awarded Arne Sloth Jensen its annual prize. In 1991, the technology was acclaimed with the French award for nonpolluting and energy saving technology offered by the organisation APAVE. In Australia in 1994 Arne Sloth Jensen received the Award for Innovation in Drying at the Ninth International Drying Symposium presented by prof. M. Hasatani, Nagoya University, Japan. |

|

|

|

|

|

|

|

|